The precision reducer used in the global industrial robot is basically monopolized by Japan. In recent years, although there are mass production RV reducer in China, few domestic robot enterprises choose it. At present, the reducer in Chinese market generally depends on import.

Japanese Yasukawa robot cuts peas with a knife

As a traditional manufacturing power, the reducer products of Germany, Italy, Japan and other countries are in the leading position in the aspects of material, design level, quality control, precision, power density, reliability and service life.

In the field of mechanical transmission, the reducer is an intermediate device connecting the power source and the actuator. It usually reduces the speed of the motor, internal combustion engine and other high-speed power through the input shaft pinion meshing the large gear on the output shaft to achieve the purpose of deceleration and transmit greater torque.

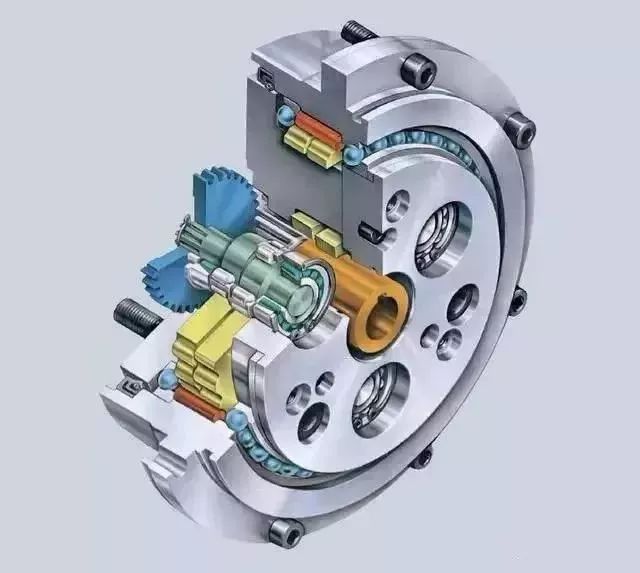

Driven by the development of aerospace, robots and medical devices, the demand for high-performance precision reducer with simple and compact structure, high transmission power, low noise and stable transmission is increasing, among which RV reducer and harmonic reducer are the important two kinds of precision reducer.

The precision reducer is a kind of power transmission mechanism, which uses the speed converter of the gear to slow down the rotation number of the motor to the desired number of revolutions and obtain a larger torque.

The precision reducer is a kind of power transmission mechanism, which uses the speed converter of the gear to slow down the rotation number of the motor to the desired number of revolutions and obtain a larger torque.

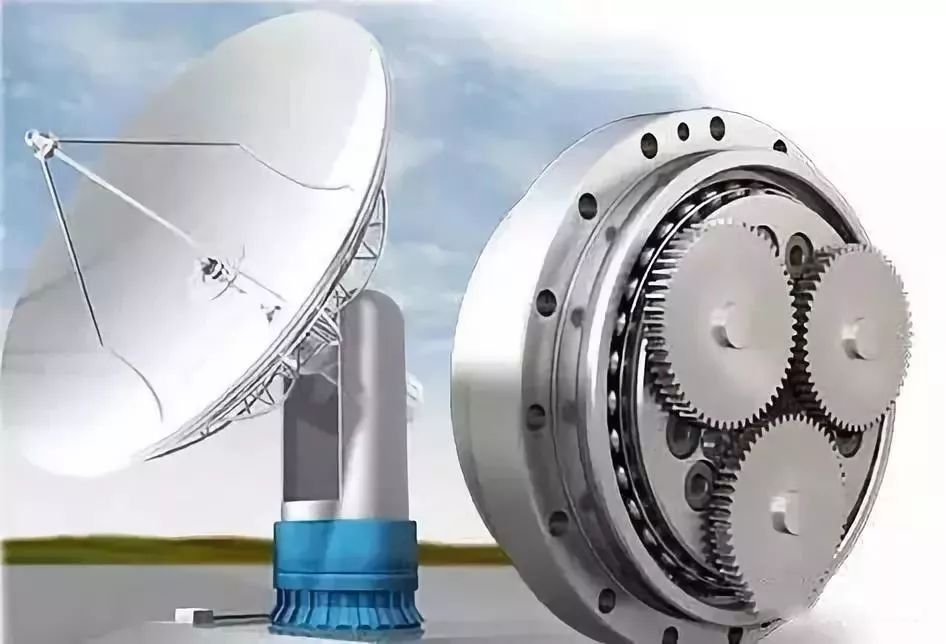

Its precision equipment not only has the ability of high torque, high rigidity and high overload impact load, but also has high precision and very low return gap. It is widely used in satellite, radar antenna, industrial robot, semiconductor and welding technology and other industrial automation fields.

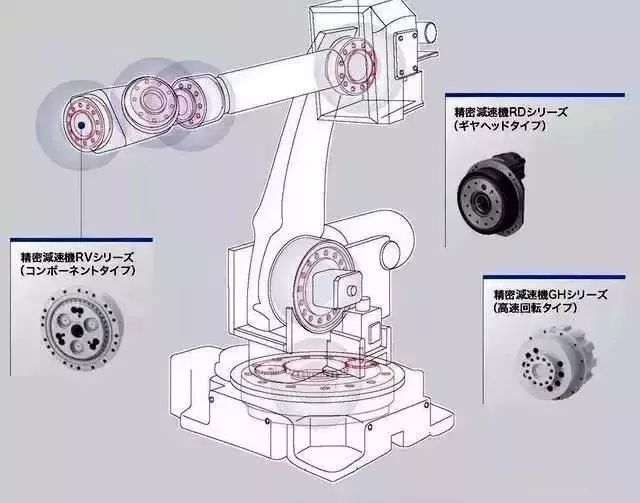

Application of Precision Reducer in each Joint of Industrial Robot

Japan Harmonic Drive Systems Inc.

(abbreviated as HDSI) is a leading enterprise in overall motion control. Its Harmonic Drive combined harmonic reducer has the characteristics of light weight, small size, no gear clearance, high torque capacity and so on. It is widely used in industrial robots, humanoid robots, semiconductor liquid crystal production devices, photovoltaic equipment, optical instruments, precision machine tools and other cutting-edge fields.

Internal structure of Harmonic Reducer.

In order to cover the field of low deceleration ratio which can not be achieved by harmonic reducer, HDSI products also involve precision planetary gear box harmonic reducer Harmonic Planetary.

The unique internal gear ring deformation technology can make the planetary gear mesh more tightly, eliminate the back clearance, and has reached the precision level of transmission error.

Harmonic Planetary Gears Harmonic Planetary Reducer.

Harmonic drive reducer is a kind of gear drive system which relies on wave generator to produce controllable elastic deformation of flexible gear, mesh with rigid gear and transfer motion and power from scratch.

Harmonic Planetary Gears Harmonic Planetary Reducer.

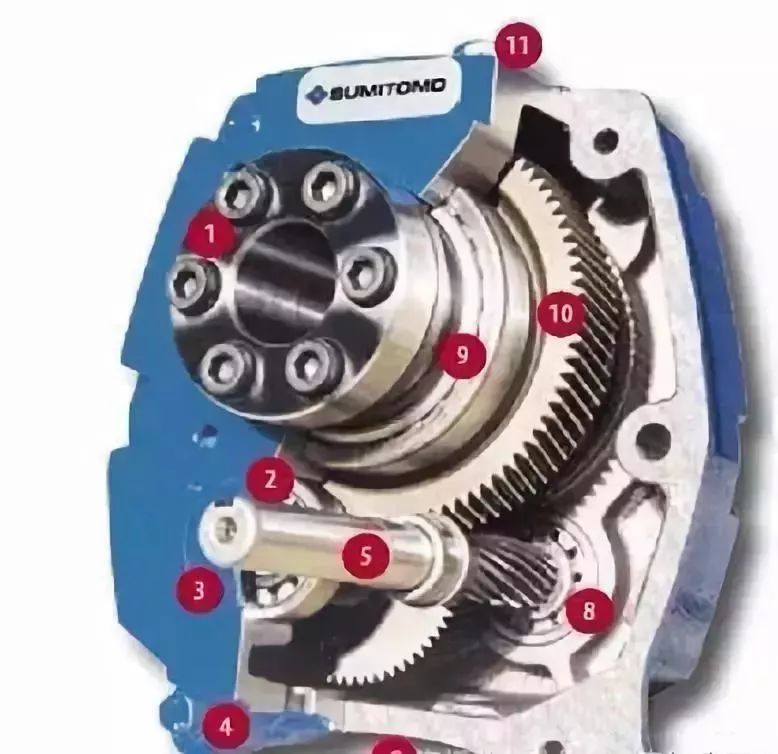

Sumitomo SUMITOMO of Japan is one of the top 500 Sumitomo Group construction machinery manufacturers with a history of more than 400 years. Sumitomo products developed the first hydraulic excavator with their own technology in 1967. At present, Sumitomo hydraulic excavators are active all over the world.

Sumitomo reducer.

Sumitomo reducer includes various types of reducer, such as Sumitomo large helical gear reducer, Sumitomo planet gear reducer, Sumitomo helical gear reducer, Sumitomo worm gear reducer and so on.

The deceleration ratio is large, the efficiency is high, the needle teeth meshing system sleeve rolling friction, there is no relative sliding on the meshing surface, and the first-order deceleration efficiency can reach 94%.

As a pinnacle of the precision machinery industry, the technical threshold of the reducer is very high. The RV reducer is completely composed of high-precision components and gears meshing with each other, which puts forward extremely high requirements for material science, precision machining equipment, machining accuracy, assembly technology and high-precision testing technology.